Painting equipment, also known as fuel injection equipment:

Paint spray equipment according to different: high-pressure air spraying, low-pressure air spraying, airless spraying, electrostatic spraying.

1. Airless spray: building decoration \ steel \ shipyard

2. Low-pressure air spraying: generators, power stations and so on

3.High-pressure air spraying: spray paint on the surface of workpiece through high-pressure air

⑴ by spraying methods Category: manual spraying, fixed gun rotating spraying, plane reciprocating machine spraying, spraying machine from top to bottom, robot spraying, DISC spraying

⑵ by delivery mode: chain type, the tunnel plane, hanging

⑶ workpiece: plastic, wood, glass, metal, ceramics, stone and so on

⑷ process:

① a coating of a baking (plastic products): → preheat (50 ℃, 3min) → automatic electrostatic dusting → fixed gun rotating spray → curing (60 ℃, 20min) → finished lower parts.

(50 ℃, 3min) → automatic electrostatic dusting → fixed gun spin coating → IR homogenization section (50 ℃, 5min) → fixed gun rotating spray → UV (plastic products) Light curing → finished lower parts.

③ a coating of a baking (glass): on → preheat (50 ℃, 3min) → automatic electrostatic dusting → fixed gun spin coating → curing (150 ℃, 20min) → cooling (5min) → finished lower parts.

④ two coating two roast: upper → preheat (50 ℃, 3min) → automatic electrostatic dusting → fixed gun spin coating → low temperature leveling (80 ℃, 5min) → fixed gun spin coating → curing (150 ℃, 20min) → Cooling (5min) → finished lower parts.

4. Electrostatic spraying:

(1) Overview: the use of electrostatic generator generates a negative voltage of 3-10 million volts through the gun head in the vicinity of the needle to form electrostatic field, the paint through a certain pressure to spray gun through the electrostatic field to bring negative charge, Sprayed workpiece ground to form a positive pole. In short, positive (workpiece) and negative (dusting) to attract each other, so that dust evenly fly to the surface, the utilization rate is very high, up to 90%. The traditional powder spraying adopts high pressure air direct spray, the utilization rate is only 30-40%.

⑵ workpiece: metal products (conductive objects), including iron products, aluminum products, stainless steel and so on.

Glass products (improved equipment to become conductive objects)

⑶ by spraying: manual electrostatic spraying, up and down reciprocating machine static, spray electrostatic spraying spin cup, DISC spraying

⑷ process (glass):

① a coating of a roast: upper → preheat (50 ℃, 3min) → automatic electrostatic dusting → rotating electrostatic spin coating → curing (150 ℃, 20min) → cooling (5min) → the next product.

② two coated two roasted: the upper → preheat (50 ℃, 3min) → automatic electrostatic dusting → rotating rotating electrostatic spray spin → low temperature leveling (80 ℃, 5min) → rotating electrostatic spin coating → curing (150 ℃, 20min ) → cooling (5min) → the next product.

5. Painting equipment, including: pre-treatment equipment, spray gun, paint room, oven, transmission line.

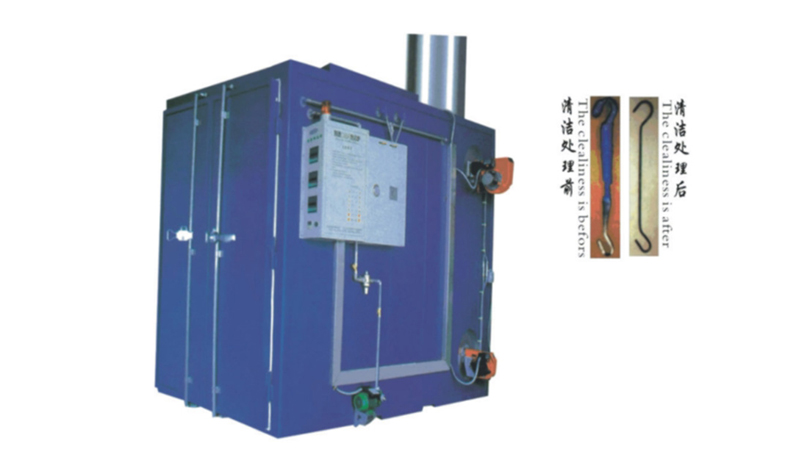

⑴ pre-treatment equipment (metal or glass products): trough-type pre-treatment, automatic processing line.

⑵ gun: air gun, electrostatic spray gun, rotating cup (hanging cup), DISC

Air gun: Japan Iwata W-101, Polaroid, Ming Li

Electrostatic spray gun: same, the Japanese Lan Shi

⑶ spray paint: cabinet, exhaust fan, water pump + water supply pipe, electronic control system

6. Auxiliary equipment: clean room, fresh air supply system, filtration equipment + Air Shower, duct, waste gas treatment, wastewater treatment.

7. Matching products: air compressor, pre-treatment syrup, oil paint, water-based paint, air spray gun, electrostatic painting, fixture, floor paint, waste water treatment AB agent.